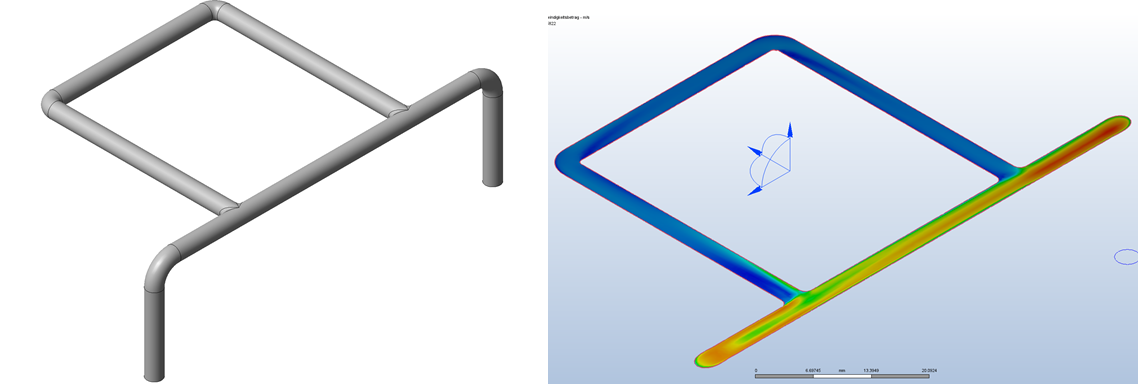

Conformal cooling takes a different approach to solving these process challenges. As the name implies, it involves the design of cooling channels that conform to, or are capable of copying, the surface of the mold cavity. The best way to manufacture this conformal channel system is through the use of metal additive manufacturing, in particular, through the powder bed technology known as Selective Laser Melting (SLM). Addimen (https://www.addimen.com/en/services/mould-inserts/), a leader in the design and manufacture of inserts with conformal cooling has been committed for years to this technology, which is already mature in countries such as Germany and is becoming increasingly popular in our country. The advantages come from the combination of freedom of design (necessary to manufacture the curved channels inside the insert), availability of technical materials and the ability to hybridize the insert with a machined dowel to reduce the cost of the insert.

The most relevant design aspects for designing and manufacturing a 3D printed injection molded insert are:

- Diameter of the channels and distance to the surface: they will vary depending on the material to be injected, for the case of aluminum injection it is vital to maintain a minimum flow rate to ensure that no cavitations (punctual evaporations of the coolant) occur in the bends. The presence of this type of phenomena conditions the life of the insert.

- Number of channels in parallel: the configuration of channels in parallel is very useful to improve the flow rate. However, it is necessary to size the inlet correctly.

- Balancing: when designing parallel channels, they should be sized in such a way that they are all balanced in flow rate.

- Geometry of the channel cross-section: additive manufacturing makes it possible to manufacture channels with a non-circular cross-section or even with a variable cross-section. However, the associated head loss must be taken into account and should only be applied in certain scenarios.

In the case of hybridizing additive manufacturing with machining on the same insert, the manufacturer’s experience in the manufacturing strategy and the material selected are particularly relevant. The materials selected must be taken into account so as not to generate internal stresses or undesired galvanic couples. The most commonly used material is martensitic steel 1.2709, which can be delivered with a hardness of 45 HRC or 55 HRC depending on the application. For high-temperature and high-abrasion tooling applications, such as forging or hot stamping, Addimen is developing together with powder metal suppliers materials up to 62 HRC. The inserts made by this technology are manufactured with a stock and then brought to the required dimensions by machining.

Thanks to conformal cooling, it is possible to obtain a cycle time reduction of up to 70 % in some cases, better quality of the injected part by cooling it more homogeneously, accelerate the development of the mold and obtain it in a short delivery time.

Añade un comentario