For conformal cooling to be a long-lasting solution, two main objectives must be met:

The first is to achieve a high flow volume through all cooling channels. If the flow velocity is reduced in one area, suspended particles start to agglomerate and clog a cooling channel. This process can be minimized with a filter, but in the end no filter can prevent calcination.

The second objective is the possibility of maintenance and cleaning. If each cooling channel cannot be reached separately, cleaning liquids should be used. It is important to note that cleaning fluids also do not have the ability to fully restore the original cooling quality, resulting in uneven cooling and quality problems.

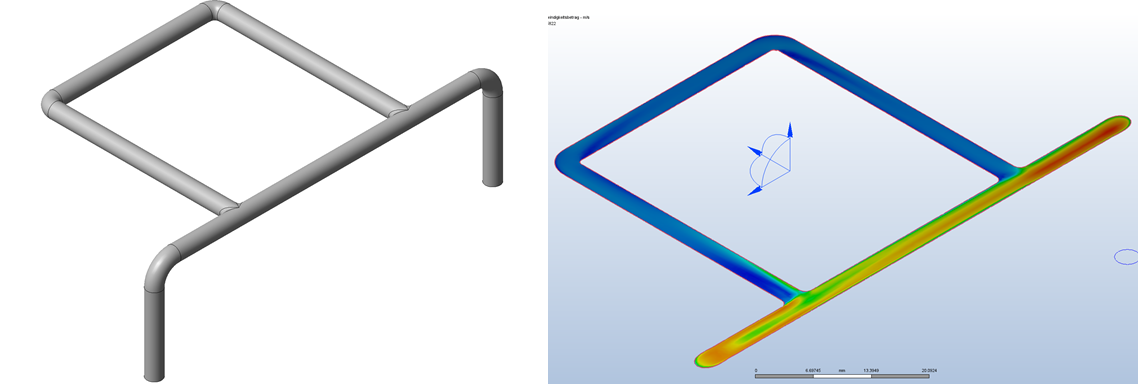

The design shown in the picture does not meet any of the objectives. The bifurcation right in the middle results in two cooling channels with large flow difference. Almost 80% of the water flows through the straight part. Moreover, if the longer channel becomes clogged, it will be impossible to clean it and the only possibility to achieve the original cooling quality will be to replace the expensive insert with a new one.

To avoid this, it will be necessary to design channels with the same flow resistance in all their branches and to allow for maintenance. This saves a lot of money, as the original cooling quality can be guaranteed for the entire lifetime of the mold.

Añade un comentario