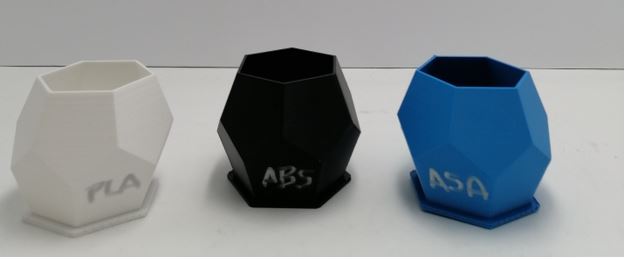

PLA, ABS and ASA are three of the most commonly used plastics in 3D printing. However, although all three are thermoplastic polymers (they flow when heat is applied) that can be printed more or less easily, they have very different properties that define their applications.

Polylactic acid (PLA) comes from natural sources such as starch and is biodegradable, so its sustainability is unmatched by its other two competitors whose origin is petroleum. Other advantages of PLA are its ease of processing (lower extrusion temperature) and good surface finish, especially for aesthetic parts. However, its mechanical properties are limited, especially when PLA is subjected to temperatures as low as 55-60ºC.

Acrylonitrile butadiene styrene (ABS) is made up of three different monomers. Each monomer provides certain properties. As a whole, ABS has a good set of properties such as strength, flexibility and durability. On the other hand, its heat resistance is far superior to PLA, which makes it maintain a much wider operating range. This is the reason why ABS is overtaking PLA and why Addimen recommends it, especially for parts with even low mechanical requirements. The low extra cost for the material is fully justified in most cases. However, ABS is prone to warping and cracking if the process temperatures (bed, chamber and extruder) are not well controlled.

Another factor to take into account is that ABS is soluble in acetone making it possible to polish parts made with this material in a simple way. Thus, although PLA comes out of the extruder with a better surface finish, ABS and ASA have the option of being able to improve their appearance with acetone vapors.

To conclude the comparison, acrylate-styrene-acrylonitrile (ASA) has very similar properties to ABS but is particularly resistant to weathering, sunlight, saturated hydrocarbons, oils, aqueous salt solutions and some alcohols. Therefore, the extra cost of using ASA instead of ABS is only justified when the part will be exposed to the elements mentioned above.

A common element of ABS and ASA is that they release small amounts of styrene during printing. This factor means that printing with these materials should be done in ventilated rooms.

Añade un comentario