Addimen, the company

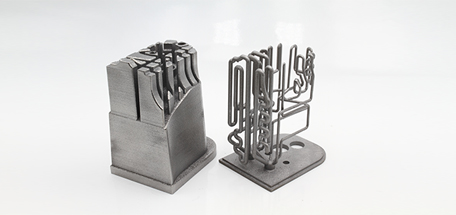

Addimen was founded in Bizkaia in 2014 by three partners from the sheet metal processing field. Their entrepreneurial nature led them to create a company aiming to be leaders in additive metal manufacturing, proposing innovative solutions and unique designs.

In 2018, Gonvarri Industries, a leading multinational company in the transformation of steel and aluminium became a shareholder of Addimen, demonstrating its commitment to new technology and innovation.

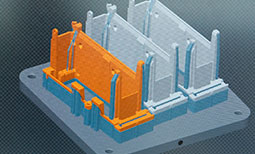

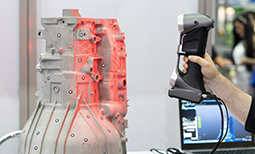

Nowadays, Addimen has positioned itself as a benchmark company in 3D printing services in metal and polymer, offering unique solutions in different industrial sectors.