3D Printing

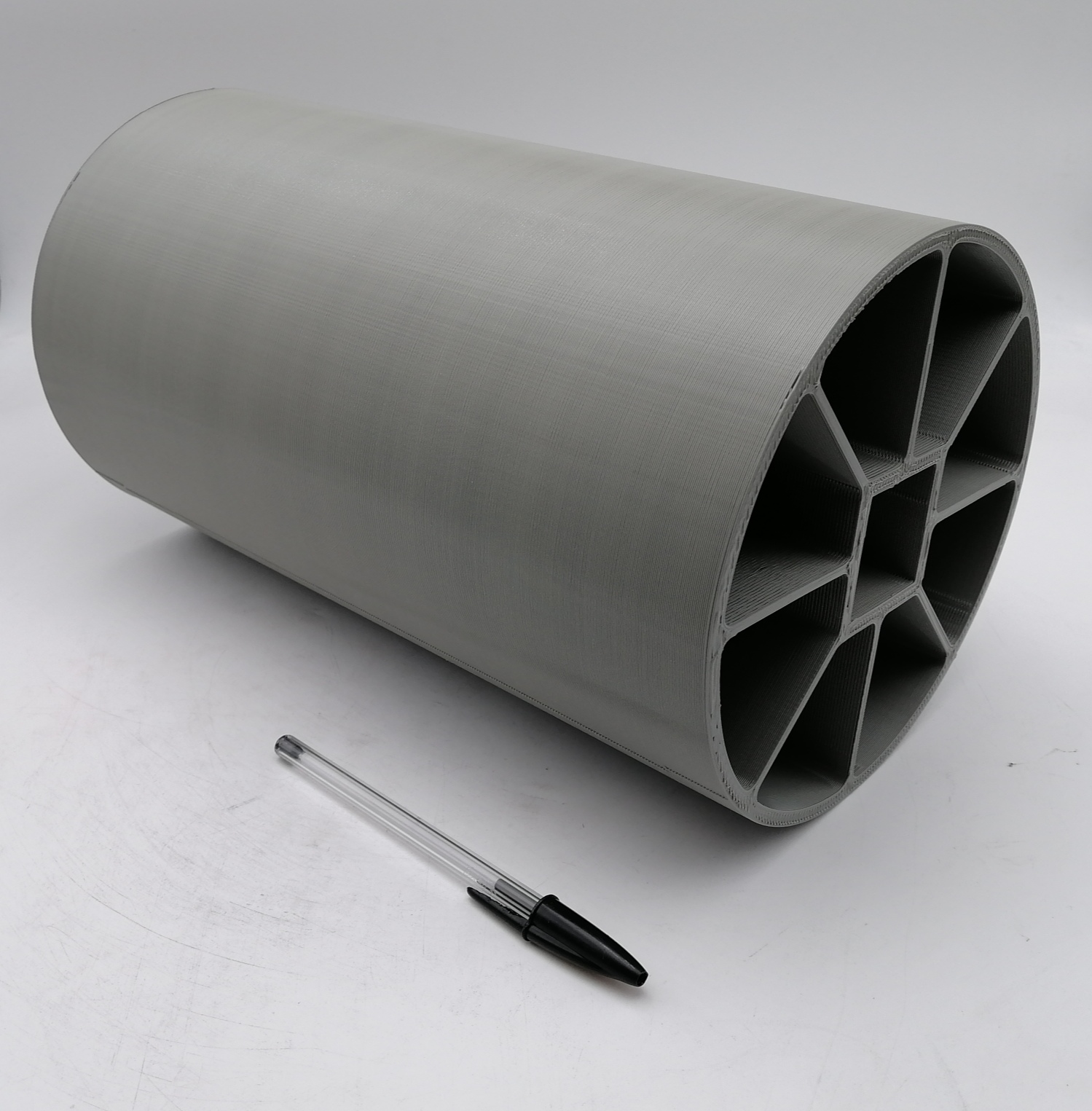

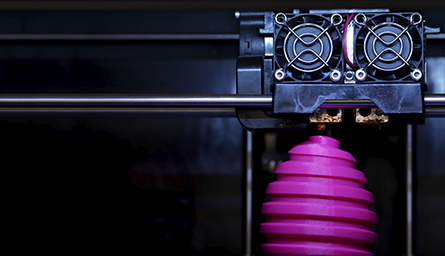

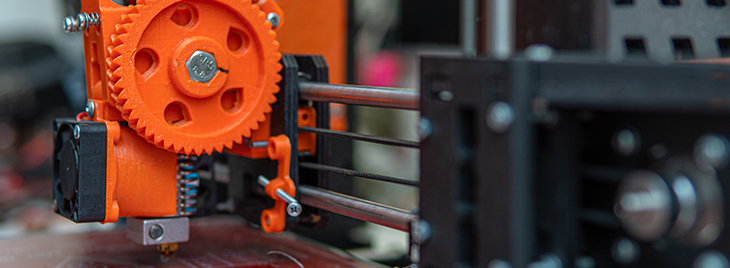

3D printing, also known as additive manufacturing, is a process through which objects are designed and created in 3D through the addition of material layers based on a digital model. 3D printing of material first starts with an initial design, also known as additive engineering, where the designer creates their design of the part to be produced with the intention that it will be manufactured using additive technology, instead of subtractive technology, getting as much as possible out of the 3D printers.