Metal 3D printing

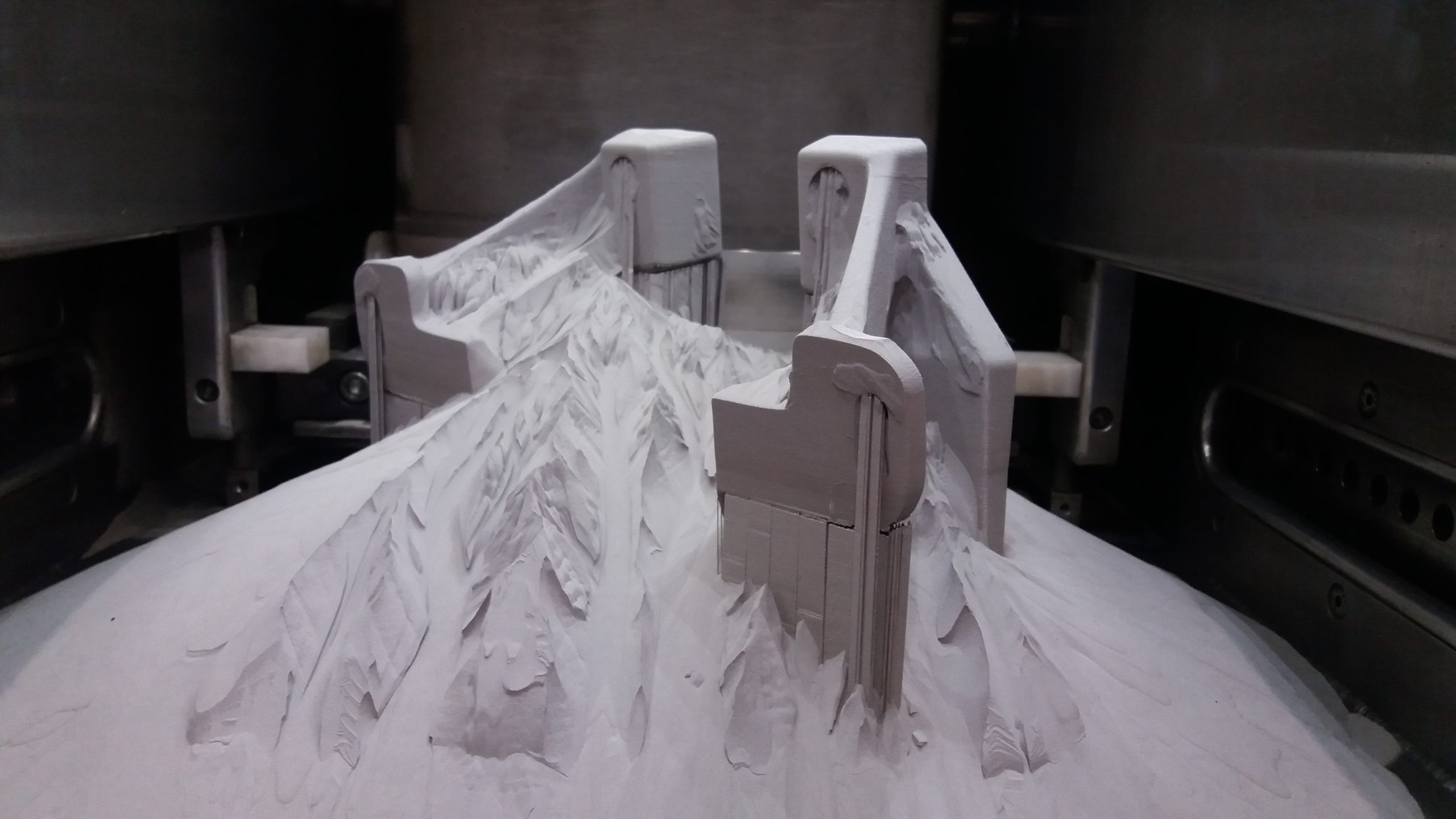

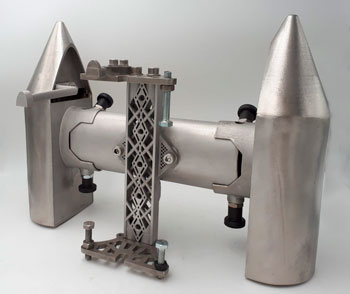

3D printing with metal is the creation process of a metal part in 3D from a digital file. Additive manufacturing, also known as 3D printing, gets its name as it involves the creation of a final model through the overlaying of various thin layers of material. At Addimen, we are specialists in Selective Laser Melting (SLM) technology. This technology differs from other 3D metal printing techniques due to the increased density (over 99.5%) of the parts, the increased dimensional accuracy, and the absence of binders.