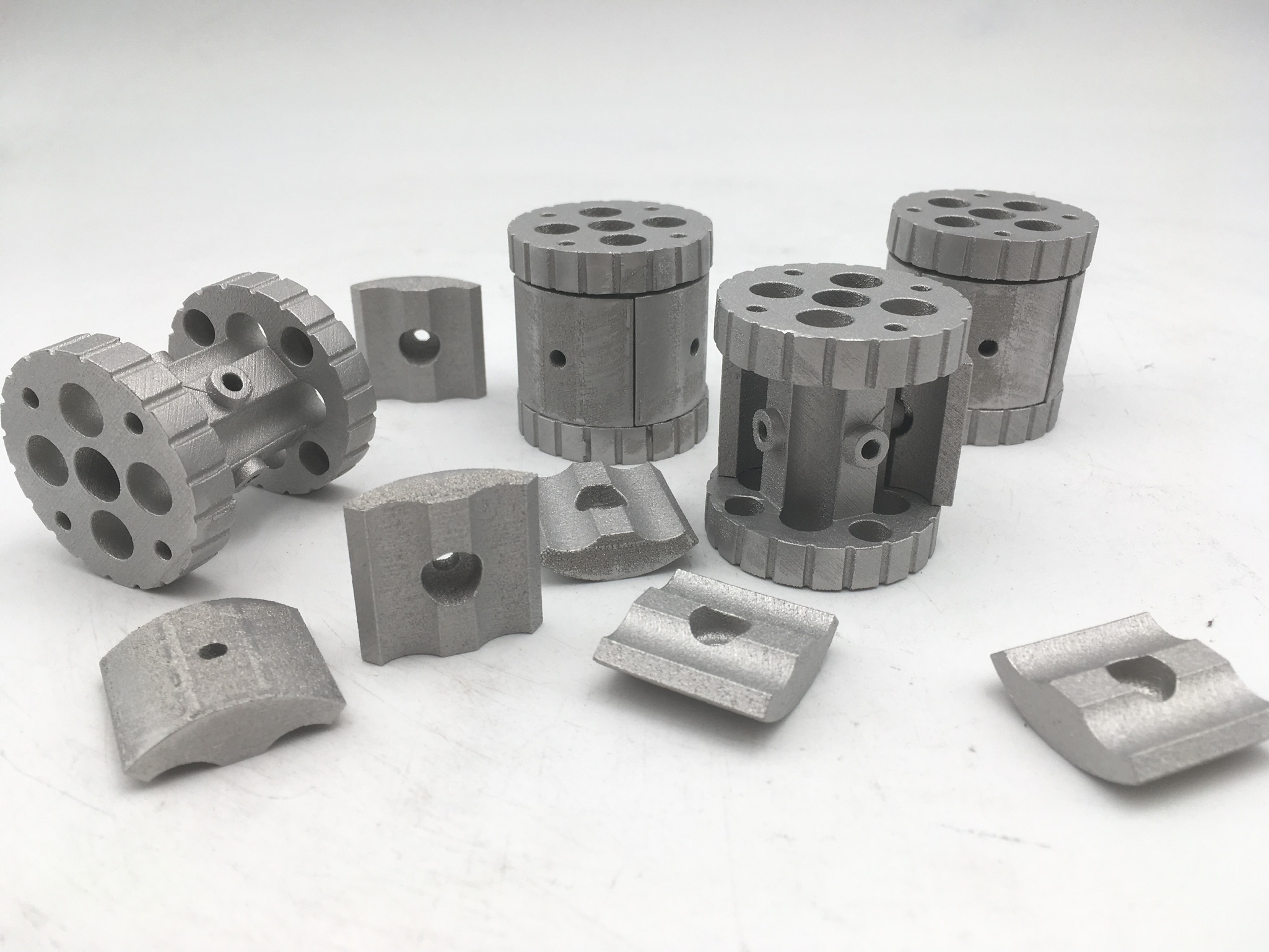

Spares on demand

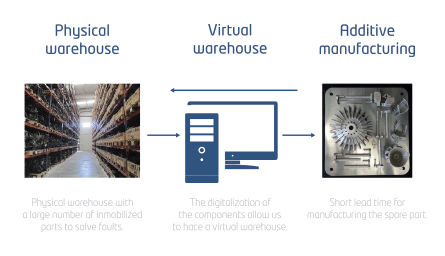

Industrial processes are increasingly more flexible and versatile, meaning that the variety of spares available is often almost infinite. Additionally, the cost and shipping times of some spares can be high, meaning that these are a fixed warehouse item for many companies. In other cases, some industrial machines are so old that there are no longer any manufacturers of the spares. In these cases, 3D printing can offer unique solutions to make industrial processes even more efficient. As the original part was designed to be manufactured by conventional methods, it is important to carry out an adaptation and validation process of the printed spare.