Mercedes Benz

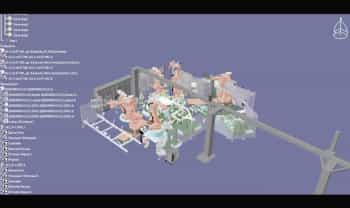

Mercedes Benz, as a car manufacturer, has highly automated assembly plants. This high number of robots means that the arms and mechanisms associated with these are extensive, and they require personalisation. Additionally, when the collective weight of the parts that need to be assembled is particularly high, the robot suffers a lot when turning its arm, resulting in tooling breakages, downtimes, and increased consumption.