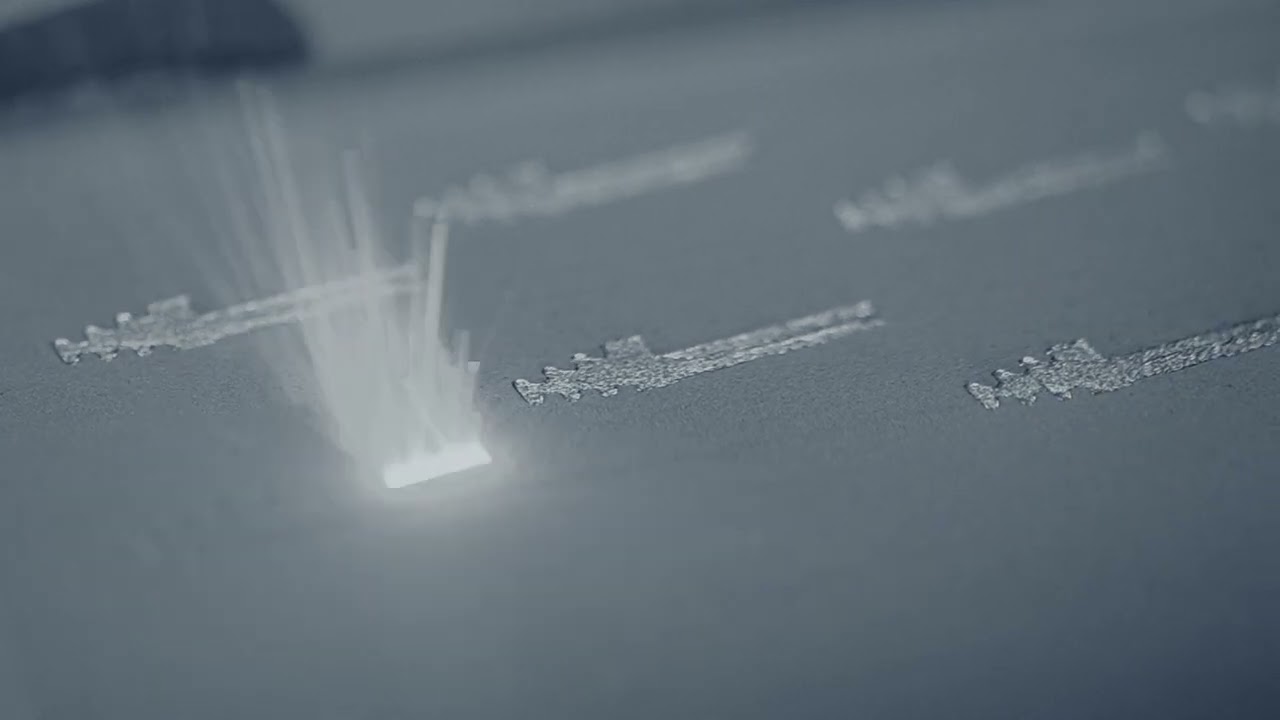

SLS 3D printing technology

Selective Laser sintering (SLS) is a powder bed technology that uses polymer powders. A laser beam allows particles to be selectively fused within a temperature-controlled chamber in such a way that the powder is self-supporting and there is no need for support structures. This technology offers excellent finishes with almost no post-processing. The optimal balance between properties and price has made SLS technology the most demanded technology in the industry.